Najbolji u klasi za prototipove i male serije

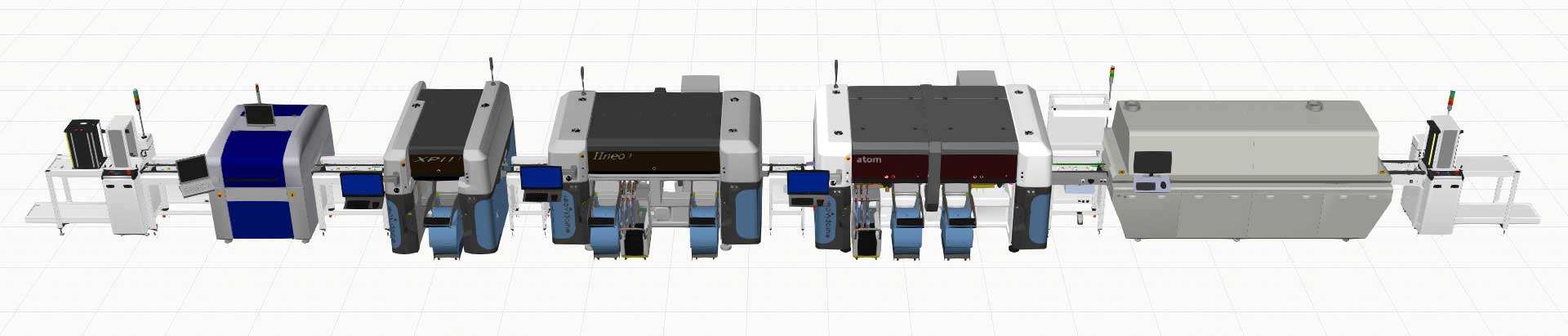

S ii-N1 u vašoj proizvodnoj liniji, više nikada ne morate reći ne. Platforma se temelji na jedinstvenoj višekernelnoj tehnologiji obrade Europlacera, dizajniranoj za rješavanje svih zahtjeva površinskog montiranja bez kompromisa. Uvođenjem elegantnog ii-N1 stroja povećat ćete produktivnost i osigurati vrhunske performanse za bilo koju aplikaciju sastavljanja.

RC 5.16

RC 5.16 is the latest version of the Europlacer graphical

user interface, featuring a wider touch-screen monitor

to facilitate fast and easy navigation across the graphical

menus.

• Microsoft® Windows® 10 64-bit OS

• Clear Graphical User Interface for ease of operation

• Multi core management to speed up vision analysis, program placement optimisation and internal communication

• Embedded Jedec Tray library capability

• Enhanced Package Library:

• Display non-optimal package settings with option to override

• Exact shape representation for different device types (segmented, flip chip, etc.)

• Display and adjust position of pin 1 on each package

• New special analysis mode for difficult devices

• Electrical test wizard, with picking and placing test interface

• Server/Client management of databases to reduce traffic on the user network, resulting in higher communication speeds and support for multiple machine installations - up to 9 machines per line

• Enhanced analysis of multi leaded or balled devices using high resolution fixed camera

• Online documentation

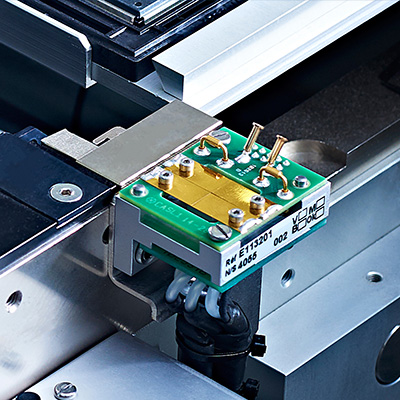

COMPONENT TESTER

Europlacer’s integrated component tester is an essential option for manufacturers operating in high specification fields, such as automotive, military, medical or aviation. The tester can be independently calibrated against all internationally recognised standards and standards institutes. Dynamic testing during component placement guarantees the statutory performance required when working on demanding applications. Europlacer’s electrical test head is mounted inside the machine structure, without compromising any platform resources or the feeder count. The head comprises a four-wire Kelvin-connected LCR measuring bridge linked to a flexible circuit test pad. This is where the machine places the components to be measured between the pick and place actions.

ii-N1 offers two proven technologically

advanced packs supplied at a commercially

attractive level

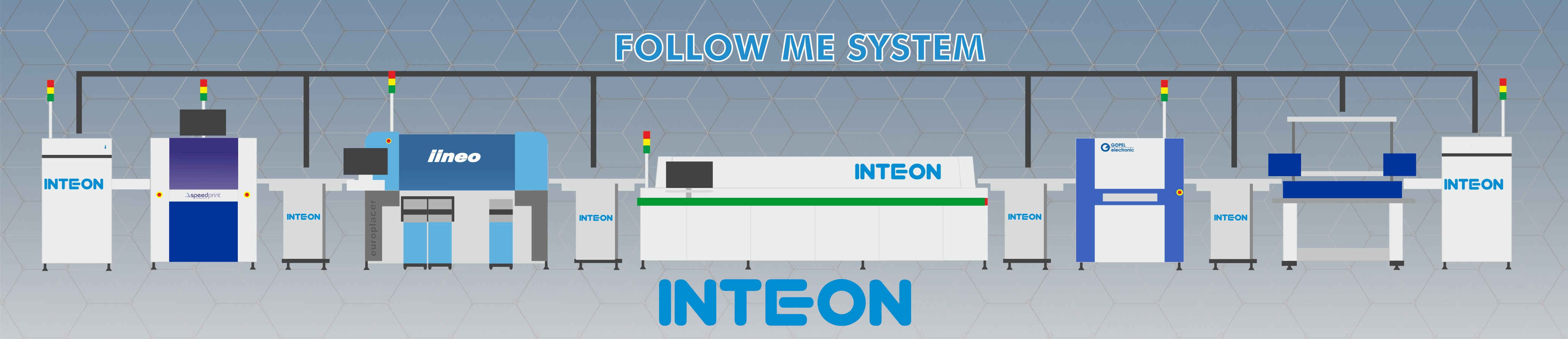

TRACK PACK

An upgrade pack that bundles Europlacer’s Total Traceability and PROMON options to take 1D and 2D traceability to a new level. Track Pack also adds an auto width conveyor, programming station and microterminal.

AERO PACK

A high-integrity ESD upgrade pack that extends the standard ESD compliance beyond the board transport and pick & place mechanisms to the entire iineo+ platform.

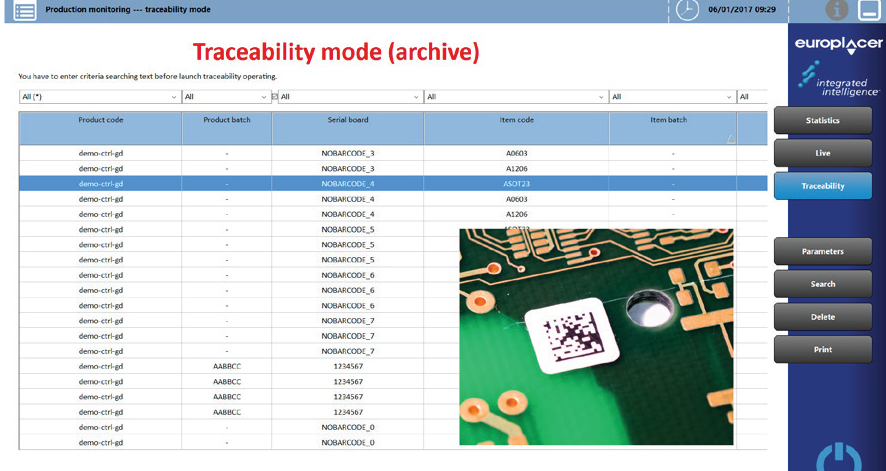

TOTAL TRACEABILITYTM

Total Traceability lets users integrate full traceability into the production process. This intelligent system provides comprehensive data logging for component-level build traceability, generating data for every board produced. The PCB camera reads board codes while the intelligent feeders hold batch data. The archive can be processed by PROMON production monitoring software or exported for traceability analysis. Based on product identification, the system also permits automatic program loading to streamline changeover.

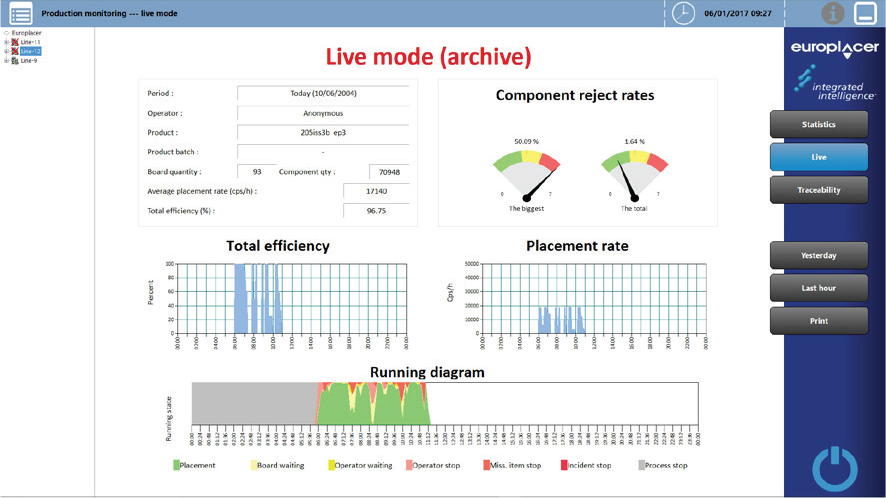

PROMON

Serving as a production ‘dashboard’ for Europlacer machines, PROMON provides an easy-to-use single source of production management data. It continually collects and stores all production data from a machine, a single line, or multiple lines, with Live Mode allowing real-time viewing and local or remote analysis. Statistical Mode can analyse data over a specified period. With quantity data needed for management and reporting, and performance data instrumental in optimising productivity, PROMON is an ideal tool to analyse and search traceability data.